Determination of Structural Parameters of Turkish Coals

Energy demand of the world is increasing constantly while coal still keeps its value as one of the primary sources of energy to supply this demand. Turkey has one of the largest lignite deposits in Europe with total estimated reserves of 11.5 billion tons [1]. For effective development and utilization of these coal resources, scientific investigation into its chemical structure is necessary, which is lacking today. In Sabancı University, we work on the information on structural parameters of Turkish coals determined by X-ray diffraction, Raman , FTIR and NMR spectroscopy.

On the other hand, uncontrollable utilization of coal as an energy source has negative impacts on the environment. For this reason,

Sabancı University Chemistry Department has investigated alternative processes to produce clean energy from coal. In order to achieve that, extraction and production of natural gas from coal has become a more significant subject for the energy providers. Coal bed methane (CBM) production is a large and clean energy source with many advantages. In the USA, 10 % percent of natural gas demand has been supplied by CBM [2]. CBM may have thermogenic or biogenic origin and the coal gas is adsorbed in the porous coal surface. Production of the secondary biogenic methane by utilization of additional microorganisms has been studied by Sabancı University, aiming to obtain more clean energy from coal.

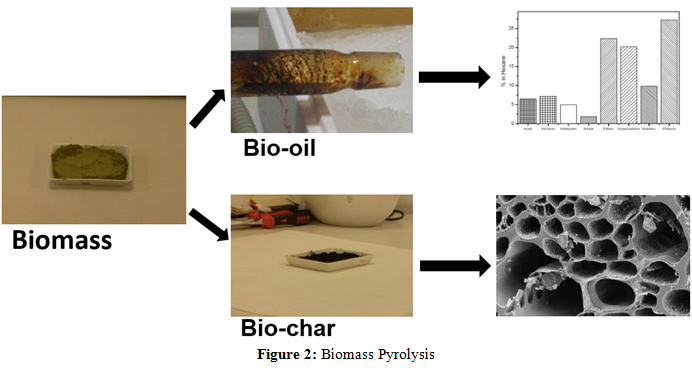

Biomass Pyrolysis to Produce New Energy Sources

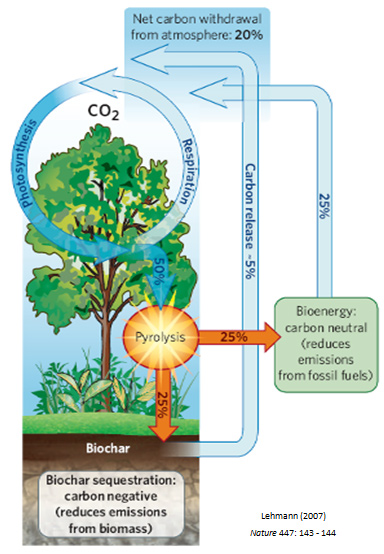

Biomass is one of the strongest candidates as the solution to the ever increasing energy demand of the world, owing to its easy processibility and zero carbon emission to the atmosphere.

However, low energy density and short storage time decreases its feasibility. Sabancı University Chemistry program’s studies have shown that storable and high energy content liquid product can easily be obtained by pyrolysis. For favorable usage of bio-oil, it must retain its initial physical properties for long time storage and transportation. That means that secondary reactions with unstable oxygenated products such as carboxylic acids, aldehydes and ketones decrease stability, which is called "aging", causes energy content loss of the bio-oil [3]. In our laboratories, conventional and fast pyrolysis methods are used to produce bio-oil from biomass. Also, characteristic change of the bio-oil composition with the help of catalytic pyrolysis by using mesoporous materials and their transition metal complexes are investigated.

- Lignite Sector Report, Turkish Coal Enterprise, Ministry of Energy and Natural Resources, 2010.

- Harris, S.H., R.L. Smith, and C.E. Barker, Microbial and chemical factors influencing methane production in laboratory incubations of low-rank subsurface coals. International Journal of Coal Geology 2008. 76: p. 46-51.

- Adam, J.; Blazso, M.; Meszaros, E.; Stöcker, M.; Nilsen M. H.; Bouzga, A.; Hustad, J. E.; Grønli, M.; Øye G. Fuel, 2005, 84, 1494–1502